Introduction

Underground control cables are an essential component of modern infrastructure, facilitating the transmission of signals and power for a wide range of applications. These cables are buried beneath the ground, providing a reliable and efficient means of connecting control systems across various industries. In this article, we will explore the intricacies of underground control cables, including their installation, benefits, and maintenance requirements.

Overview of Underground Control Cables

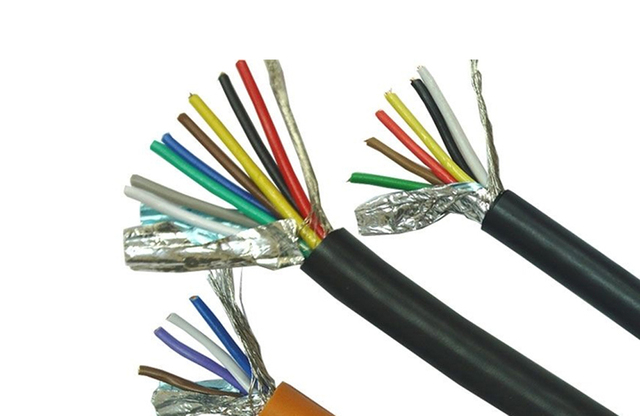

Underground control cables are insulated conductors that are designed to transmit electrical signals for control purposes. Unlike power cables that primarily carry electricity for lighting, heating, and other electrical appliances, control cables are used to transmit signals for the operation of control systems. These systems can be found in various industries, including manufacturing, transportation, telecommunications, and more.

The design of underground control cables is crucial to ensure reliable and secure signal transmission. These cables are typically made of copper or aluminum conductors, which are surrounded by insulation materials such as PVC, XLPE, or rubber. The insulation protects the conductors from environmental factors such as moisture, chemicals, and temperature fluctuations, ensuring the integrity of the signal transmission.

Installation of Underground Control Cables

The installation of underground control cables involves several key steps to ensure proper functioning and longevity. The process typically begins with a thorough planning phase, where the route of the cables is determined based on the specific requirements of the control system. Factors such as distance, terrain, and existing infrastructure must be considered during the planning phase to minimize potential disruptions and ensure efficient cable placement.

Once the route is established, the installation process begins with trenching or directional drilling to create a pathway for the cables underground. Trenching involves digging a trench along the designated route, while directional drilling uses specialized equipment to bore a hole underground without disturbing the surface. The chosen method will depend on various factors, including the soil conditions, depth of burial, and environmental regulations.

After the pathway is created, the underground control cables are laid in the trench or inserted into the drilled hole. rubber sheathed flexible cable is crucial to handle the cables with care during installation to prevent damage to the conductors or insulation. Proper cable support and securement are also essential to prevent sagging or shifting over time. Additionally, proper sealing and waterproofing measures must be taken to protect the cables from moisture and other environmental factors.

Benefits of Underground Control Cables

There are several key benefits to utilizing underground control cables for signal transmission in various applications. Some of the primary advantages include:

1. Enhanced Reliability: Underground control cables are less susceptible to external interference, such as electromagnetic interference (EMI) and radio frequency interference (RFI), compared to overhead cables. This increased reliability ensures consistent signal transmission and minimizes the risk of system downtime.

2. Aesthetics: Underground control cables are hidden from view, providing a more aesthetically pleasing environment compared to overhead cables. This can be particularly beneficial in urban areas or landscaped settings where visual impact is a concern.

3. Safety: Underground control cables eliminate the risks associated with overhead cables, such as falling debris, vandalism, and weather-related damage. This enhances safety for both workers and the general public in areas where control cables are installed.

4. Environmental Impact: Underground control cables have a lower environmental impact compared to overhead cables, as they do not require the clearing of vegetation or disruption of wildlife habitats. This environmentally friendly approach is increasingly important in modern infrastructure projects.

5. Longevity: Properly installed underground control cables have a longer service life compared to overhead cables, as they are protected from external elements such as UV radiation, weather conditions, and physical damage. This longevity results in reduced maintenance and replacement costs over time.

Maintenance of Underground Control Cables

Proper maintenance is essential to ensure the optimal performance and longevity of underground control cables. Regular inspections and preventive maintenance measures can help identify potential issues early and prevent costly downtime. Some key maintenance practices for underground control cables include:

1. Visual Inspections: Regular visual inspections of the cable route can help identify signs of damage, such as exposed cables, vegetation growth, or signs of digging or excavation near the cables. Any anomalies should be addressed promptly to prevent further damage.

2. Cable Testing: Periodic testing of underground control cables can help verify the integrity of the signal transmission and identify any potential faults or degradation in the cable insulation. Testing methods such as insulation resistance testing and continuity testing can be conducted by qualified technicians to ensure the cables are functioning properly.

3. Grounding Checks: Proper grounding is essential for the effective operation of underground control cables. Regular checks of the grounding system can help ensure that the cables are adequately protected from electrical faults and surges. Any issues with the grounding system should be addressed promptly to prevent damage to the cables.

4. Cable Marking and Identification: Proper labeling and marking of underground control cables can help facilitate maintenance and troubleshooting efforts. Each cable should be clearly identified with information such as cable type, routing, and termination points to aid in future maintenance tasks.

5. Environmental Monitoring: Monitoring environmental conditions such as temperature, moisture levels, and chemical exposure near underground control cables can help identify potential risks to the cable insulation. Implementing environmental monitoring systems can provide early warnings of adverse conditions and help prevent cable damage.

Conclusion

Underground control cables play a vital role in modern infrastructure, providing a reliable and efficient means of transmitting signals for control systems across various industries. The installation, benefits, and maintenance of these cables are essential considerations for ensuring optimal performance and longevity. By following best practices in cable installation and maintenance, organizations can maximize the benefits of underground control cables while minimizing downtime and maintenance costs.